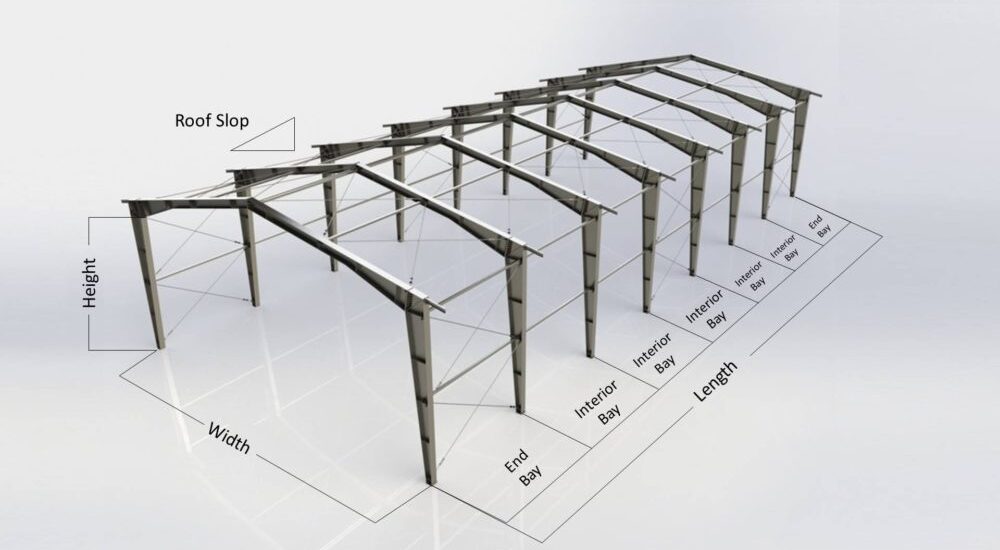

The basic parameters that define a pre-engineered building are:

Building Width is defined as the distance from outside of eave strut of one sidewall to outside of eave strut of the opposite sidewall. This does not include the width of Lean-To buildings or roof extension:

Building Length is longitudinal length of the building measured from out to out of end wall steel lines.

Building Height is the eave height which is the distance from the bottom of the main frame column base plate to the top outer point of the eave strut. When columns are recessed or elevated from finished floor, eave height is the distance from finished floor level to top of eave strut.

Clear height is the distance from the bottom of the main frame column base plate or finished floor level to the inner point of the eave strut at side.

Roof Slope (x/10) is the angle of the roof with respect to the horizontal. The most common roof slopes are 0.5/10 and 1/10. However any practical roof slope is possible.

End bay length is distance from outside of the outer flange of end wall columns to center line of the first interior frame column.

Interior bay length is distance between the center lines of two adjacent interior main frame columns. The most common bay lengths are 6 m, 7.5 m and 9 m.

Design Loads unless otherwise specified PEBs are designed for the following minimum loads:

Roof Live Load: 0.57 kN/m2

Design Wind Speed: 110 km/h

Design for snow loads, earth quake loads, collateral loads, crane loads or any other loading condition, if required must be specified at the time of request for quotation.

Loads are applied in accordance with American codes and standards applicable to pre-engineered building unless otherwise requested at the time of quotation.

Design as per MBMA:

The 2002 Edition of Low Rise Building System Manual of Metal Building Manufacture Association (MBMA).

All applicable loads are as per MBMA

Hot rolled and build up section are designed in accordance with:

Manual of Steel Construction, 9th Edition of American Institue of Steel Construction (AISI).

Cold – Formed members are designed in accordance with:

1996 Edition of Cold-Formed Steel Design Manual of American Iron and Steel Institute (AISI).

Welding is applied in accordance with:

Structural Steel Welding Code of American Welding Society (AWS.D1.98).

Design as per Indian Standard:

IS – 875 (Part I) – 1987: Code of Practice for Design Dead Loads for Building and Structures.

IS – 875 (Part II) – 1987: Code of Practice for Design Imposed Loads for Building and Structures.

IS – 875 (Part III) – 1987: Code of Practice for Design Wind Loads for Building and Structures.

IS – 1893 (Part I) – 2002: Criteria for Earthquake Resistance Design of Structures.

IS 2062: 2006 – Steel for general structural purposes.

IS 808: 1989 – Dimensions for hot rolled steel beams, columns, channels and angles.

Design of prismatic Hot rolled and built up section is in accordance with:

IS – 800 (1984 & 2007): Code of Practice for General Construction in Steel.

Design of Tapered Built up section is in accordance with:

Manual of Steel Construction, 9th Edition of American Institute of Steel Construction (AISC).

Cold – Formed members are designed in accordance with:

IS – 801 (1975): Code of Practice for use of Cold – Formed Light Gauge Steel Structure.

Welding is applied in accordance with:

Structural Steel Welding code of American Welding Society (AWS D1.1.98)

IS – 816 (1969): Code of Practice for use of Metal Arc Welding for general construction

LOTUS PRE-ENGINEERED BUILDINGS

Lotus Pre-engineered buildings are high in demand, owing to their unmatched quality and long-lasting durability. To meet the precise demands of our clients, we design these products as per their detailed specifications. Lotus Pre-engineered buildings are well-designed PEBs that are based on the PEB concept which are designed under the supervision of technocrats with international structural standards keeping in view. Then these buildings are fabricated in our state-of-the-art manufacturing unit by taking optimum quality raw material given by the trusted and certified vendors of the market. These Building components are shipped to the project site and erected by our expert team with complete safety.